Telescopic Power Manipulator

A remote control device that can perform various tasks perfectly in radioactively contaminated areas that are inaccessible to human workers

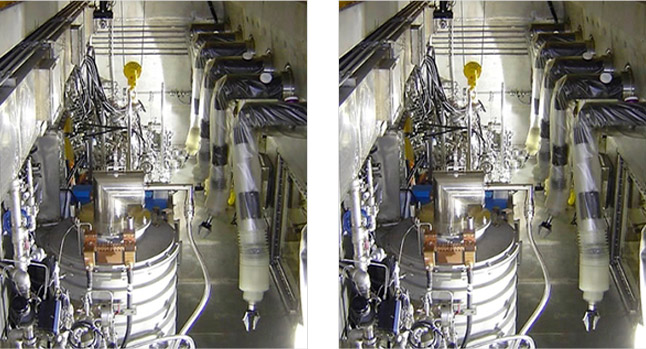

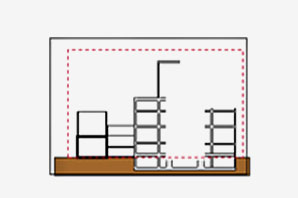

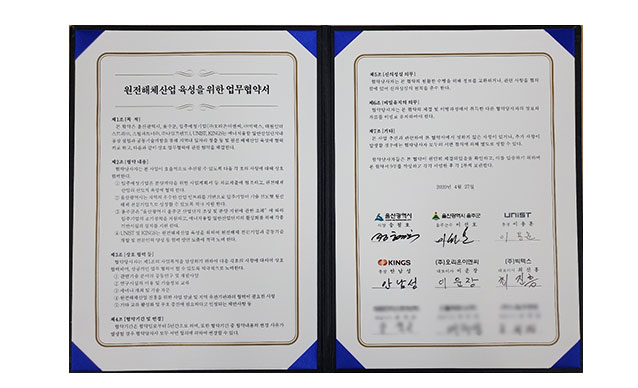

Overview of nuclear power plant decommissioning and remote robot system

A system that can be operated remotely from a safe distance away due to radioactive contamination or chemicals

-

Used to handle research facilities, waste, etc. in hot cells

Used to handle research facilities, waste, etc. in hot cells -

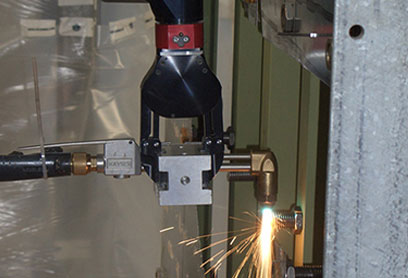

Used for nuclear power plant dismantling work

Used for nuclear power plant dismantling work

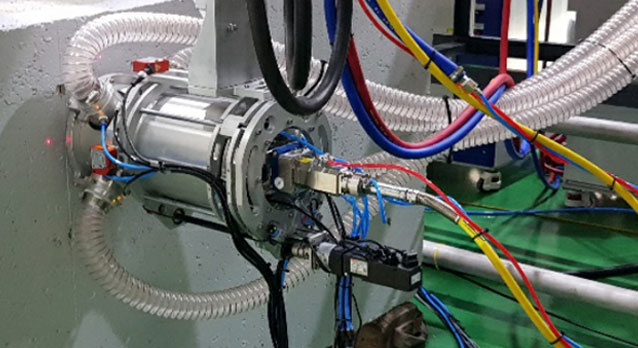

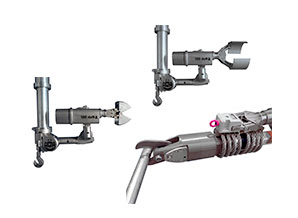

Victex remote servo manipulator (installed in the heavy ion accelerator facility)

Remote servo manipulator demonstration video

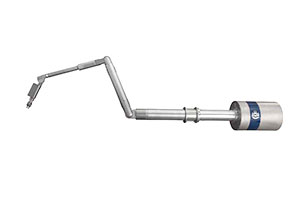

Victex remote telescopic servo manipulator

Telescopic Master-slave Manipulator A100

- ·Mainly used to remotely control hot cell internal operations

- ·Operation by the operator is accurately reproduced

- ·Can be used by both left-handed and right-handed people

- ·A variety of work is possible with a variety of tools

- ·Ergonomic control panel

- ·Light and easy to operate with smooth movement

- ·The same force as that of a human hand is transferred to the Slave Arm, which can perform work in precision

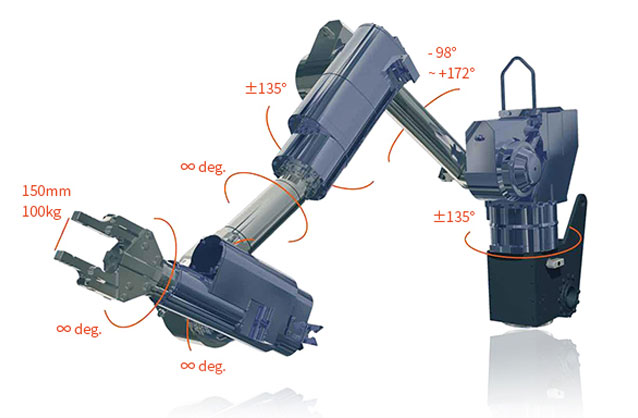

Servo Manipulator A1000S

A1000S is a servo manipulator based on A1000 and has the advantages of A1000.

It has Cartesian control, and is specialized in handling heavy objects in hot cells, dismantling nuclear power plants, decommissioning, decontamination, and maintenance.

Precise and easy operation is possible through Go-To-mode and 3D simulation.

A pre-positioning system is installed, allowing flexible and wide range of work.

- Main work

-

- ·Handling of radioactive substances

- ·Dismantling / Decommissioning

- ·Decontamination

- ·Maintenance

- ·Heavy weight handling in hot cells

| Max. vertical range | 7.1m |

| Max. horizontal range | 4m |

| A 1000S arm length | 2.5m |

| Max. load capacity | 100kg |

| Motion axes type | Articulated |

| A1000 arm axes | 6 joint axes + tool axis |

| D.O.F(degrees of freedom) | 6 D.O.F |

| Pre-positionining system | 3 axes |

| Drive system | DC & Servo Motors |

A1000S is designed to operate in harsh environments. Constructed from high-quality materials that are radiation-resistant, acid- and corrosion-resistant, Arm has the following advantages:

- Precise movement and control

- No exposed wiring

- Almost maintenance-free

- Special coating to easily remove contaminants

- External mechanical emergency operation is possible for all joints

- Arm part can be remotely exchanged

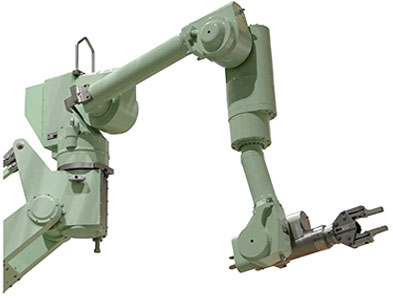

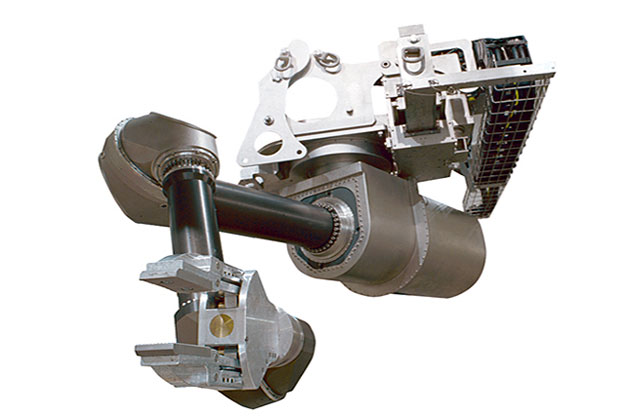

Power manipulater A1000

- ·Possible heavy-duty work that is difficult for humans to do

- ·Available to work underwater

- ·All movements use electricity

- ·SPC control system (PC-based control is also possible)

- ·The operation panel is designed to be intuitive in operation

- ·Can be operated like a crane and can be used in combination with TELBOT

- ·Easy maintenance

- ·Radiation tolerance 1000000 Gy

| Arm Capacity Weight | 200~500 kg |

| Radiation-Resistant | 1000000 Gy |

| Arm Length | 1000 ~ 4000 mm |

| Telescope Length | 1000 ~ 5000 mm |

Utilization fields

- Radioactive waste disposal machine

- Heavy weight handling in hot cells

- Dismantling work

- Process support manipulators in hot cells

- Underwater work/span>