-

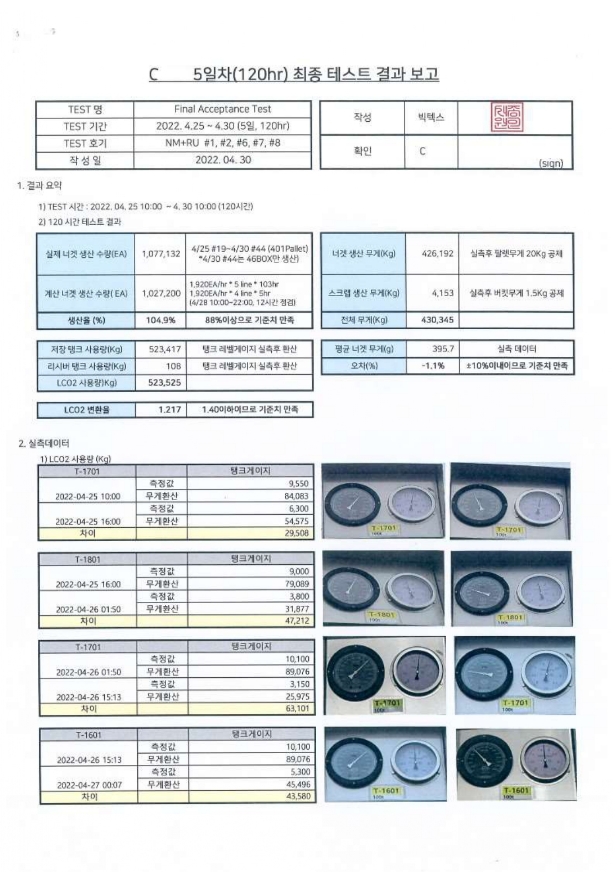

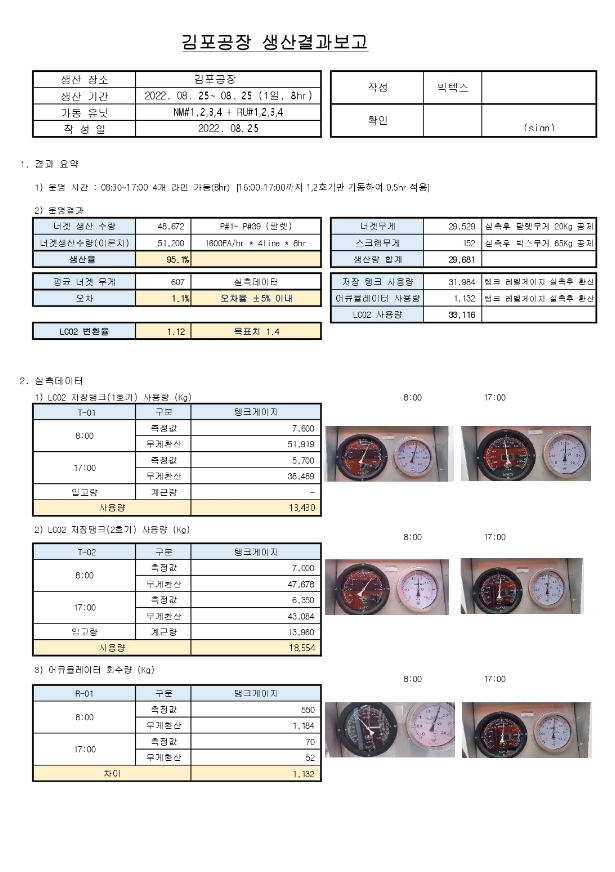

Company K Gimpo Plant Dry Ice Production Line

-

Company C Yongin Factory Dry Ice Production Line

-

Company E Gimpo Plant Dry Ice Production Line

-

Victex Incheon Plant Dry Ice Production Line

PRODUCT

Rejection of unauthorized e-mail collection

We reject unauthorized collection of e-mail addresses.

We reject unauthorized collection of e-mail addresses posted on this website using e-mail collection programs or other technical devices, and please keep in mind that violations will result in criminal penalties under the Information and Communications Network Act.

Nugget ice maker

Victex Co., Ltd. developed a dry ice maker for the first time in Korea, and has been supplying various dry ice manufacturing facilities, such as nugget ice for refrigerants and dry ice pellets for washing machines, based on excellent development personnel and design and machine manufacturing technology.

- Victex Nugget Ice Maker SNT Series

-

This is an automated facility that can continue to operate for 24 hours. Its direct pressurization of CO₂ snow in a closed chamber prevents CO₂ gas leak, its compact size maximizes space utilization, and its simple touch screen operation enables flexible changes in the production weight of dry ice (100~600g).

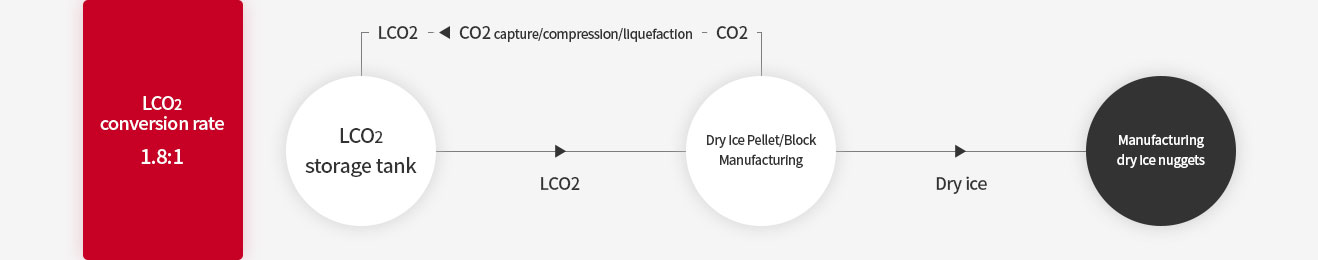

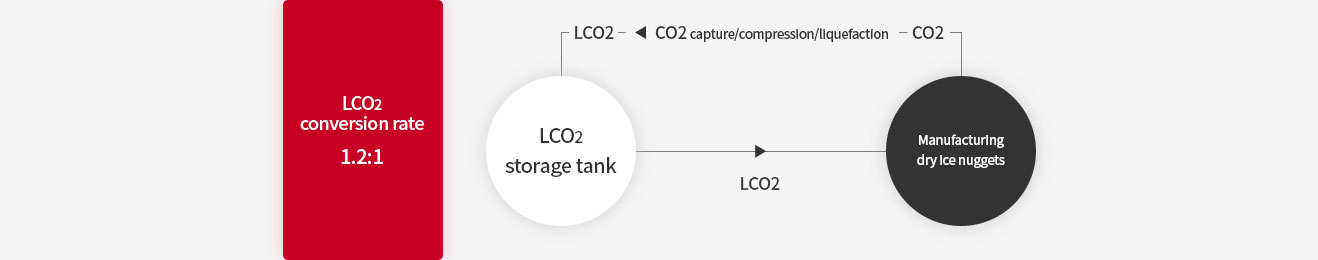

In addition, when combined with Victex's CO₂ Revert Recovery System, the CO₂ conversion rate can be maximized to 1.2:1, so 30% more dry ice can be produced with the same amount of liquefied carbon dioxide, compared to other facilities (CO₂ conversion rate 1.7~1.8:1). So, it’s economically efficient.

Specifications of nugget ice maker

| Specifications | SNT-300K-4-3-G | SNT-600K-8-3G | SNT-500K-4-6G | SBT-1000K-4-6G |

|---|---|---|---|---|

| Nugget production | 270kg/hr | 540kg/hr | 480kg/hr | 960kg/hr |

| Standard nugget weight | *300g | *600g | ||

| Changeable to 100~600g according to user settings | ||||

| Standard nugget size | *110W X 80L X 23H | *110W X 80L X 45H | ||

| Number of production / hour | 900 / hour | 1,800 / hour | 800 / hour | 1,600 / hour |

| Power(Kw) | 20KW | 37KW | 20KW | 37KW |

| time / 1 cycle | 16 second | 18 second | ||

| Nugget density | 1.50 g/cm² or more | |||

| Power supply | **380V, 3 Phase | |||

| Noise | Less than 65dB when measured from a distance of 1m outside the partition | |||

| Remark | *Nugget weight and size can be changed according to customer's request ** Power supply can be changed according to customer needs |

|||

1. Victex's LCO₂ nugget manufacturing system of snow direct pressure method

Victex's LCO₂ nugget manufacturing

system of snow direct pressure method

system of snow direct pressure method

-

Modularization and

Modularization and

miniaturization system -

High efficiency,

High efficiency,

large production line

- ∙No CO₂ loss due to direct snow pressurization (conversion ratio 1.2:1)

- ∙Minimize the sublimation rate by creating high-density (over 1.50g/cm3) dry ice nuggets through direct compression of LCO₂ snow

- ∙Modular, miniaturized and integrated system improves operation and productivity, saves more than 50% of installation space

- ∙100% self-design/manufacture/installation/operating system for all equipment such as nugget maker, transfer device, and non-woven packaging machine

- ∙Automation of the entire process through component standardization

2. How other companies make dry ice nuggets

How other companies make dry ice nuggets

-

Pellets

Pellets -

Loss of production rate

Loss of production rate

- ∙Loss of pellet production rate during pellet compression process

- ∙Loss occurrence during transfer and compression after pellet production

- ∙Multi-hydraulic system operation of pelletizer and block compressor

35kg barge block cutting dry ice maker

- ·Requires wide installation space due to large size

- ·Dry ice loss occurs in the block cutting process

- ·Requires additional installation of cutting block alignment device

- VICTEX's nugget ice maker does not manufacture nuggets by manufacturing dry ice pellets and then molding or cutting them after making dry ice blocks, but by directly pressurizing liquid carbon dioxide in the snow state to produce nuggets, the first of its kind in the world (obtained domestic patent and applied for patent in 5 countries around the world)

- There is no loss of CO2 because it is molded in a closed chamber and combined with Victex's CO₂ Revert Recovery system, it has a conversion rate (from LCO₂ to dry ice) of 1.2, increasing productivity by more than 30%, compared to 1.7~1.8 of other companies.

- Miniaturized and integrated equipment reduces production space by more than 50%

- 24-hour operation by a minimum number of personnel thanks to automation of all the processes, such as dry ice nugget manufacturing, conveyor transfer, and non-woven packaging.

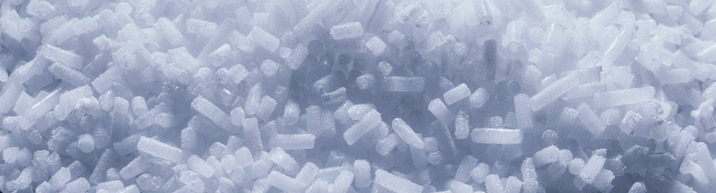

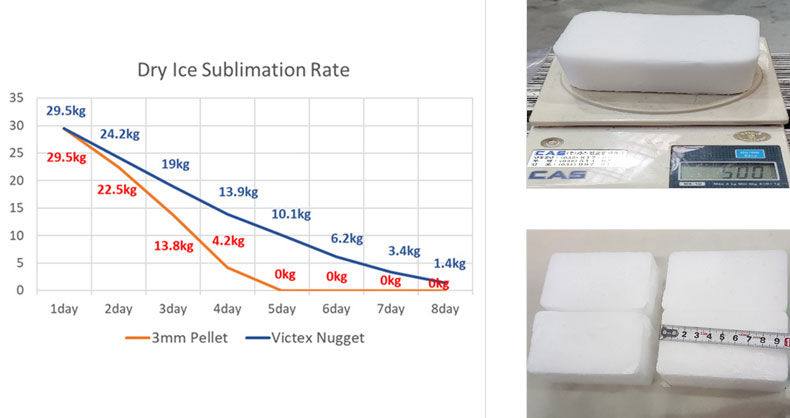

3. Excellent nugget ice quality

- Dry ice nuggets made by directly pressurizing LCO₂ snow, a unique technology of Victex, have a high compression density compared to the nuggets made by other companies which are made after pressurizing 3mm dry ice pellets, and can be used for more than 30% longer under the same conditions.

- (Complete sublimation takes 4 days for pellet compression nuggets and 8 days for Victex nuggets when nugget ice is stored at room temperature in a 30Kg box)

-

Victex Dry Ice Nuggets

Fine snow particles are compressed and the compression strength is very high

-

Third party 3mm pellet compression nuggets

Large-sized pellets are compressed, leaving many empty spaces and low compression strength

| Victex VS Dry ice sublimation rate test results | |||

|---|---|---|---|

| Date | Pellet | Victex nuggets | Difference (%) |

| Day 1 | 29.5kg | 29.5kg | 0.00% |

| Day 2 | 22.6kg | 24.2kg | -6.61% |

| Day 3 | 13.8kg | 19.0kg | -27.37% |

| Day 4 | 4.2kg | 13.9kg | -69.78% |

| Day 5 | 0.0kg | 10.1kg | -100.00% |

| Day 6 | 0.0kg | 6.2kg | - |

| Day 7 | 0.0kg | 3.4kg | - |

| Day 8 | 0.0kg | 1.4kg | - |

4. Excellent operational performance and maneuverability

- ·24 hours continuous operation

- ·Flexible change in nugget weights

- ·Easy touch screen control

-

You can operate the Victex nugget maker for 24 hours and one button operation completes production from start to finish.

You can operate the Victex nugget maker for 24 hours and one button operation completes production from start to finish. -

All control of operation is done via a simple touch screen, and the dry ice nugget weight can be freely changed from 100g to 600g or more.

All control of operation is done via a simple touch screen, and the dry ice nugget weight can be freely changed from 100g to 600g or more. -

Production history management and facility management functions are built in and web/mobile remote monitoring is possible through the SCADA system.

Production history management and facility management functions are built in and web/mobile remote monitoring is possible through the SCADA system.

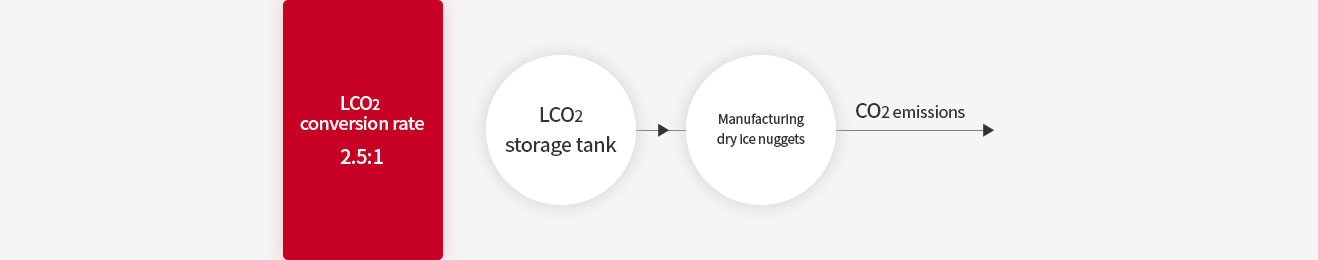

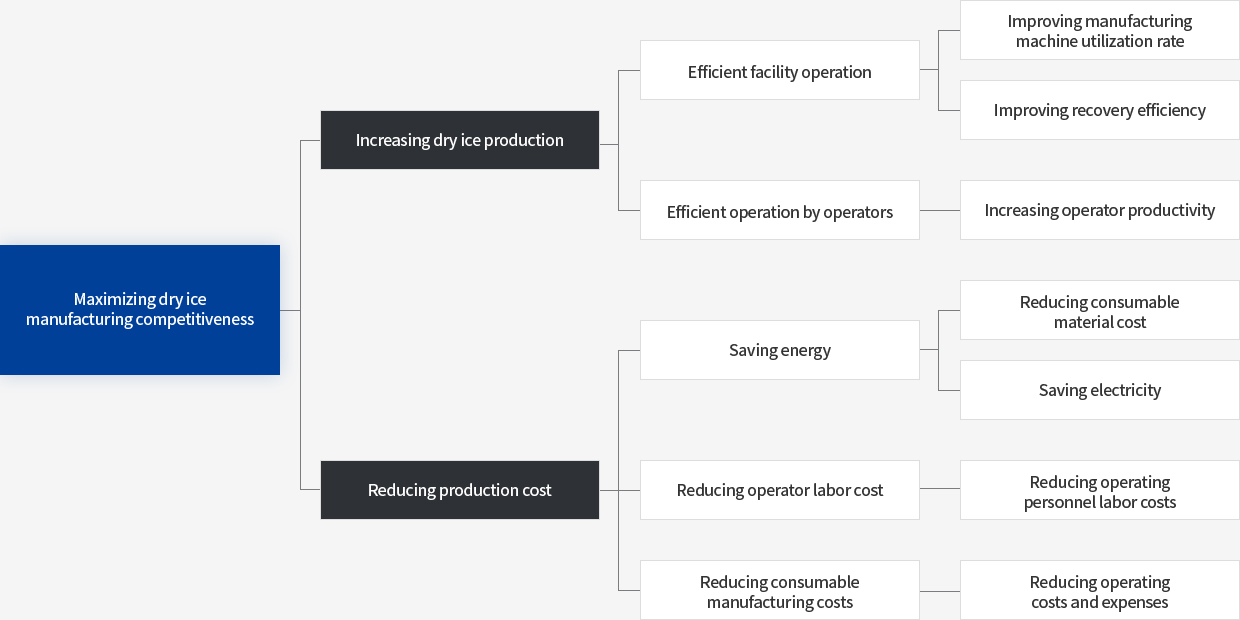

5. Reduce production cost

To minimize the loss of LCO₂ during the dry ice manufacturing process, the advanced technology of Victex Co., Ltd

1) adopts a method of directly pressurizing snow-state dry ice in a closed chamber (nugget ice maker)

2) Collects and re-liquefies all CO₂ that is discarded during the manufacturing process (CO₂ Revert Recovery system)

Through this, the LCO₂ -> dry ice conversion rate has been improved to about 1.2:1, and as a result, the production cost can be reduced by about 52%, which is a 30% reduction compared to other companies.

CASE 1: In case there is no Revert Recovery System

CASE2: In case of third-party nugget maker with Revert Recovery System applied

CASE3 : In case of Victex nugget maker with Revert Recovery System applied

6. Maintenance Program

Victex Co., Ltd.'s paid service, “Maintenance Management Program (Victex Care)” allows users of Victex's nugget maker to receive continuous service for increasing production and reducing production costs. Thus, you can receive total service to maximize dry ice manufacturing competitiveness, from operator training, breakdown repair and preliminary inspection, to dry ice quality improvement, facility performance improvement, safety and environmental preservation.