-

-

Specifications Model SSJC-2 Size 1,320(L) x 550(W) x 1,860(H) mm Weight Approx. 230 kg (without CO₂ bomb) Power 220V / 60Hz / 20A / 4.4kW CO₂ Pressure 75 ~ 90 bar Air Pressure 3 ~ 15 bar CO₂ Consumption 50~200 g/min Option Foot switch, Air filter, Customized Nozzle

PRODUCT

Rejection of unauthorized e-mail collection

We reject unauthorized collection of e-mail addresses.

We reject unauthorized collection of e-mail addresses posted on this website using e-mail collection programs or other technical devices, and please keep in mind that violations will result in criminal penalties under the Information and Communications Network Act.

Supercritical CO₂ snow jet detergent

Since Victex Co., Ltd.'s nugget ice manufacturing facility was proven for its excellent quality, durability and outstanding productivity, all three major fresh food online sellers in Korea, such as Company C, Company K, and Company E, have been using Victex's nugget ice manufacturing facilities.

Product Features

-

Spraying supercritical CO₂ for more homogeneous and powerful cleaning

-

More powerful cleaning by increasing air pressure with air buster

-

Nozzle production and automation optimized for the cleaning target

-

Easy to move and install with casters and CO₂ storage tank holder

-

No damage to objects to be washed and no secondary contaminants after washing

-

Suitable for ultra-precision cleaning with small cleaning particles and good cleaning power

Washing videos

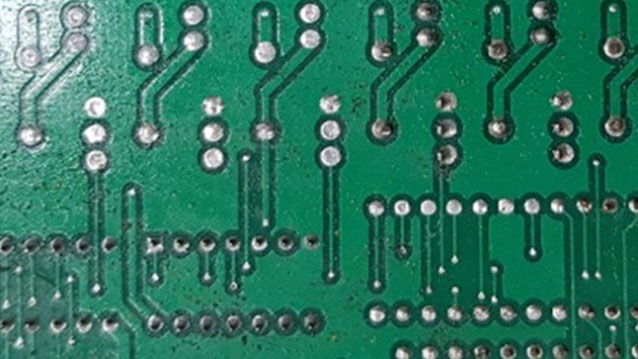

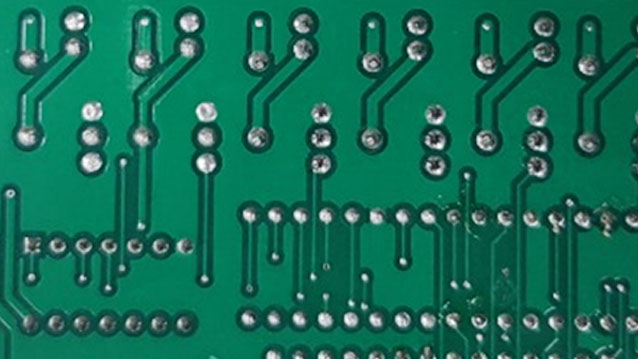

Before and after supercritical CO₂ snow jet cleaning

-

Before cleaning - mount nozzle (lead)

Before cleaning - mount nozzle (lead) -

After cleaning - mount nozzle (lead)

After cleaning - mount nozzle (lead) -

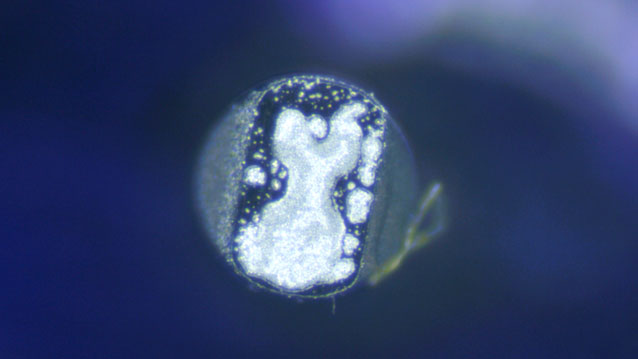

Before cleaning - spherical lenses (gas deposition)

Before cleaning - spherical lenses (gas deposition) -

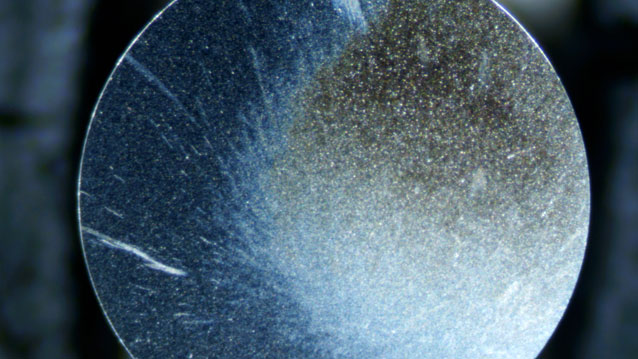

After cleaning - spherical lenses (gas deposition)

After cleaning - spherical lenses (gas deposition) -

Before washing - lens mold (oil)

Before washing - lens mold (oil) -

After cleaning - lens mold (oil)

After cleaning - lens mold (oil) -

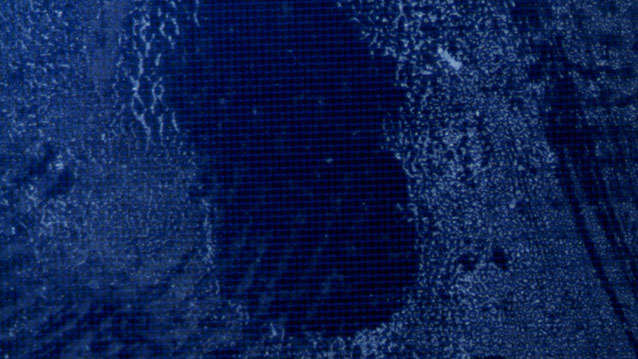

Before washing - cell phone panel (fingerprints, oil)

Before washing - cell phone panel (fingerprints, oil) -

After washing - cell phone panel (fingerprints, oil)

After washing - cell phone panel (fingerprints, oil) -

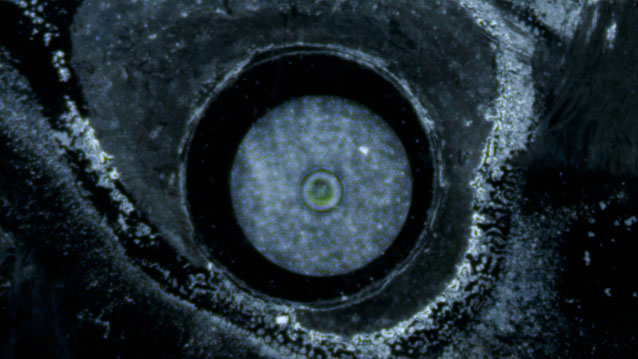

Before washing - mobile phone front camera (fingerprints, oil)

Before washing - mobile phone front camera (fingerprints, oil) -

After washing - mobile phone front camera (fingerprints, oil)

After washing - mobile phone front camera (fingerprints, oil)

Comparison of normal CO₂ washer vs. supercritical CO₂ snow jet washer

| Division | General CO₂ washer | Principle of supercritical CO₂ snow jet washer |

|---|---|---|

| Justice | Spray 55~60bar CO₂ as it is | CO₂ is boosted in pressure and sprayed in a supercritical state. |

| Cleaning power | It is difficult to remove foreign matter that is strongly fixed due to gas deposition. | Outstanding cleaning power compared to existing CO₂ cleaners, can remove foreign substances deposited in gas |

| Nozzle tip condensation | When used for a long time, there is a phenomenon that the nozzle is clogged due to dew condensation at the tip of the nozzle | No condensation |

| Condensation to be cleaned | Moisture is sprayed on the object to be cleaned or condensation occurs on the surface | No condensation |

| Air pressure | 5 ~ 10 bar | More than 5~16 bar (Air Booster can step up the pressure) |

| CO₂ storage container | Siphon type only | Both siphon and non-siphon types can be used |

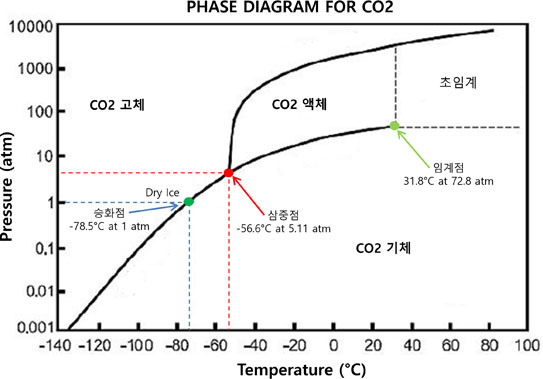

Principle of supercritical CO₂ snow jet cleaner

| Phase | Density (g/cm²) | Viscosity (g/cm s) |

|---|---|---|

| Gas | 10-⁴ | 10-⁴ |

| Supercritical Fluid | 0.3 ~ 0.8 | 10-⁴ ~ 10-³ |

| Liquid | 1 | 10-² |

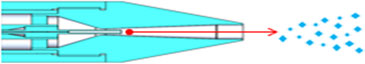

CO₂ in a supercritical state has a density similar to that of a liquid state and diffusivity, surface tension, and viscosity similar to that of gaseous currents. This feature makes the mass flow of CO2 passing through the narrow capillary relatively smoother than when it is in liquid state and when dry ice particles are created by cooling due to the pressure drop (80 bar > atmospheric pressure) at the tip of the nozzle, more and more uniform particles can be made than when spraying liquid CO2 like the existing CO2 cleaners. Hence, more cleaning power.

CO₂ snow jet cleaner

-

-

Specifications Model SJC-1 Size 400(L) x 430(W) x 221(H) mm Weight Approx. 30 kg Power 220V / 60Hz / 10A / 2.2kW CO₂ Pressure 55 ~ 60 bar Air Pressure 4 ~ 7 bar CO₂ Consumption 50~150 g/min Option Air filter, Customized Nozzle

Before and after CO₂ snow jet cleaning

-

Before washing

Before washing -

After washing

After washing -

Before washing

Before washing -

After washing

After washing

Performance and specification comparison: Snow jet VS dry ice washer

| Division | Snow jet | Dry ice washer |

|---|---|---|

| Justice | Spraying after generating dry ice from the cleaning nozzle, spraying dry ice in the form of powder | Spraying dry ice through the cleaning nozzle, spraying dry ice in the form of small granules |

| Cleaning power | Precise cleaning of fingerprints or fine dust, mainly cleaning of small objects | Cleaning with strong adhesion by deposition gas and high temperature, cleaning mainly large-volume large objects |

| Construction equipment | Snow jet cleaner, mobile LCO₂ bomb, spray nozzle, etc. | 10 ton tank, dry ice maker, dry ice washer, spray nozzle, etc. |

| LCO₂ consumption per spray nozzle | 0.3~0.5 / kg / 1Nozzle | 0.5~2.5kg / kg / 1Nozzle |

| Cleaning area per spray nozzle (nozzle size) | 0.5~2mm x 0.5~2mm | 3-5mm x 10-100mm, various |

| Air working pressure | 6 to 16 bar or more | Within 5 bar |

| Relative disadvantage | Weak cleaning power and small cleaning area per nozzle | The noise is louder than 100dB |

| Relative advantage | Delicate cleaning power and suitable for fine cleaning | Strong cleaning power and large cleaning area per nozzle |

| Dry ice particle size | 30µm ~ 1,000µm | 500µm ~ 1mm, 2mm, 3mm |

| Washing step | LCO₂ spray – Dry ice powder particle generation from nozzle – Thermal shock – Expansion, wind pressure – Separation (cleaning) | Spraying dry ice pellets through a nozzle – Thermal shock – Expansion, wind pressure – Separation (cleaning) |

| LCO₂ working pressure | above 60 bar | Within 20 bar |

Before and after CO₂ snow jet cleaning

-

Precise washing possible

-

No damage to cleaning objects

-

No secondary contaminants

-

Dry cleaning method

-

Spray Micro Type particles

-

Easy application of automation

-

CO₂ consumption and air consumption can be fine-tuned