In a strategic business alliance

with Company H, a design/construction company

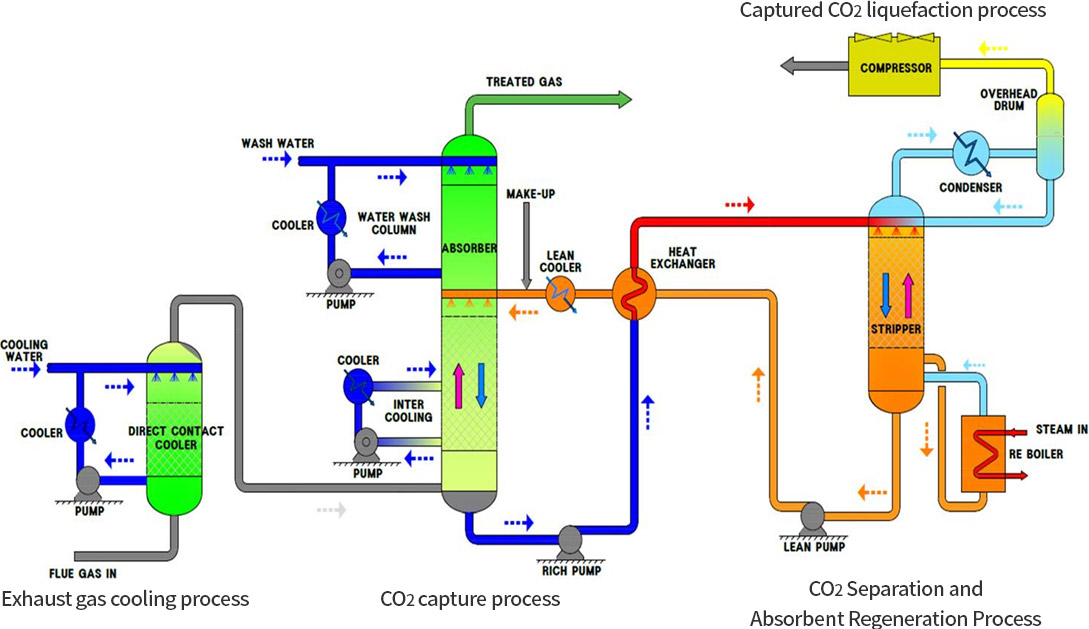

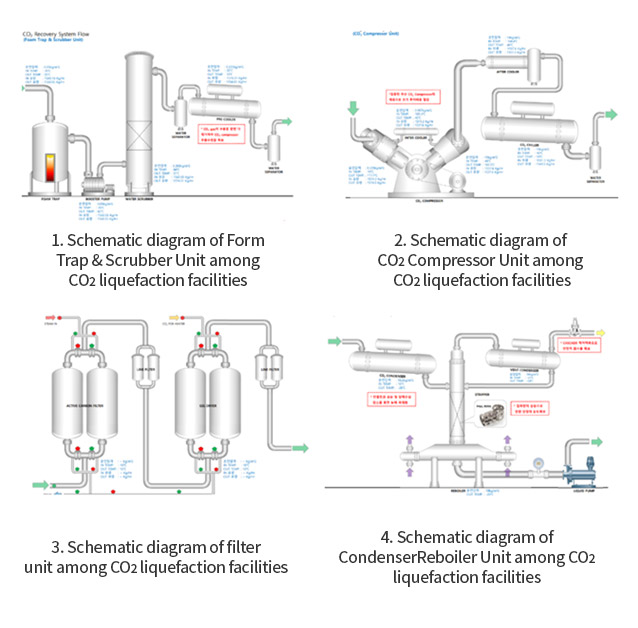

for wet amine CO₂ capture facilities, Victex Co., Ltd. has developed a technology in which carbon dioxide emitted from carbon-emitting workplaces such as power plants and steel mills is captured, purified, compressed and frozen to produce LCO₂ (liquid carbon dioxide) and maintains practical technologies ranging from the production of dry ice to the entire process of using it as a cold chain refrigerant.

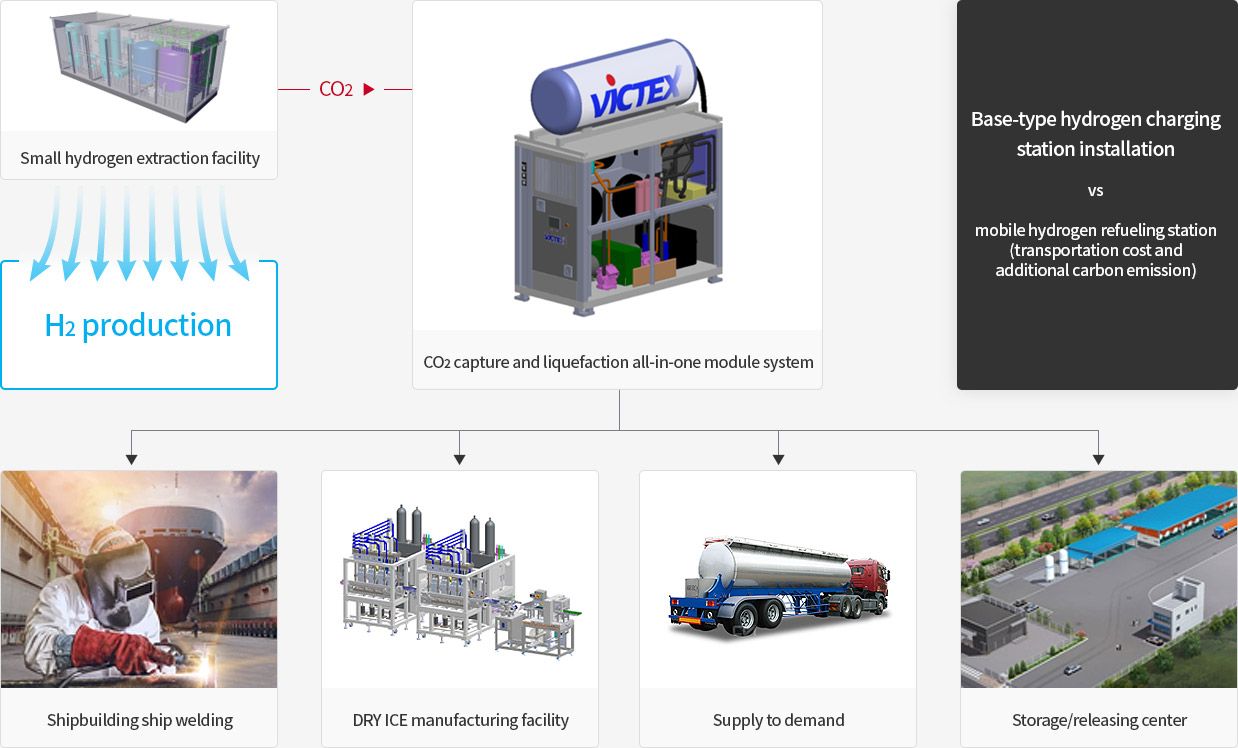

In addition, in response to base-type hydrogen production sites in the blue hydrogen production stage of moving away from fossil fuels and entering a clean hydrogen energy society, we are supplying mobile modular CO₂ capture/liquefaction equipment to capture CO2 generated as a by-product to produce dry ice and high-purity CO2 that can be used for various purposes.