Deburring system

What is deburring? (Victex dry ice deburring system)

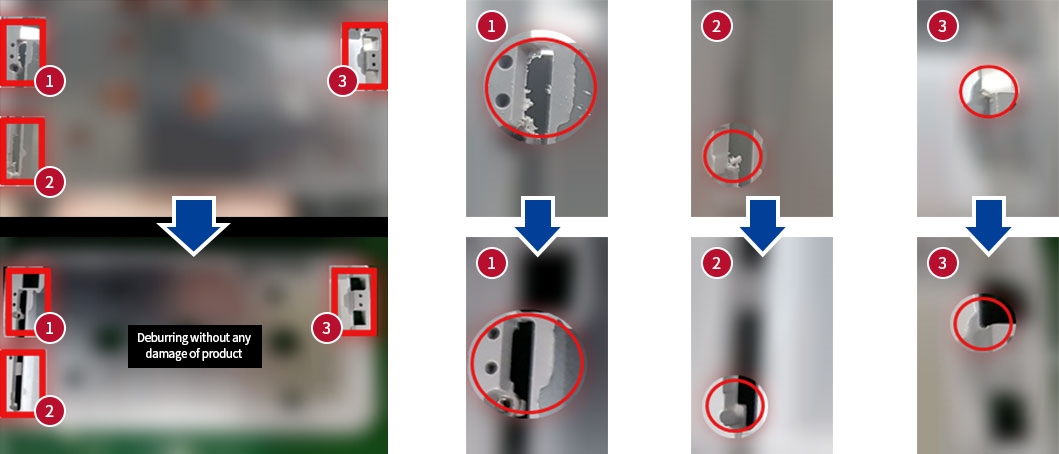

A system that completely removes unnecessarily attached burrs generated in the resin bonding process during the CNC or press or press+CNC processes of mobile phones, etc. without damaging the product.

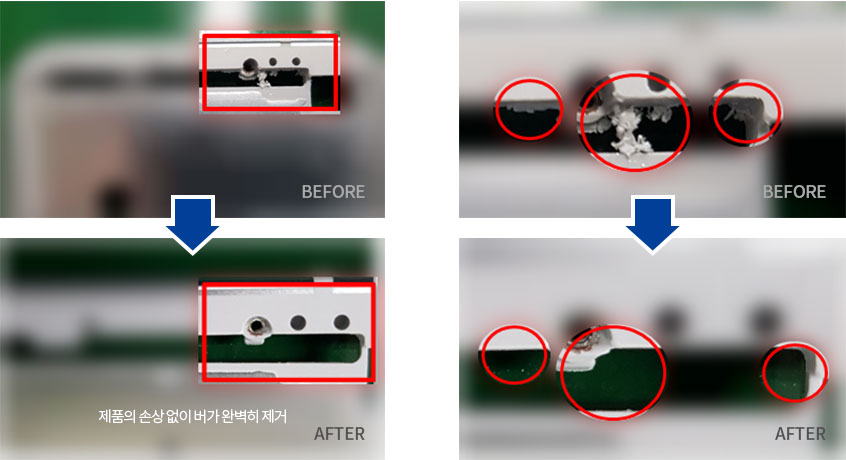

Results of the deburring test

Observation under an electron microscope confirms that the burrs are completely removed without any damage.

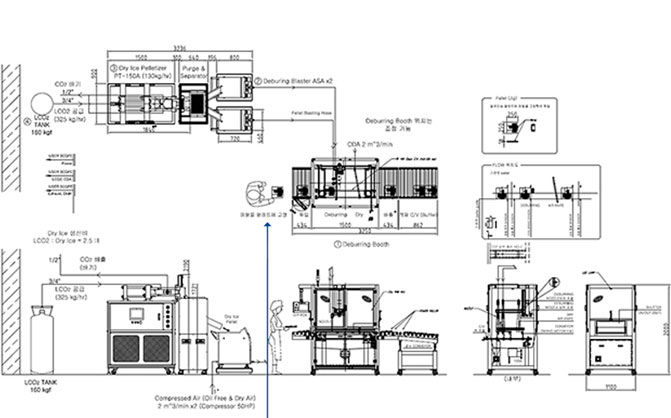

Characteristics of Victex's deburring

- Completely removes burrs without damaging the base material.

It is possible to fine-tune the deburring force under the same conditions (spray pressure, pellet spray amount per minute). (Steps 1 to 10)- •Flexible handling is possible according to the characteristics and physical properties of the base material, burr size, and burr shape.

- •Possible to adjust working conditions: It is possible to adjust the spray pressure and the amount of pellet spray while maintaining the deburring force.

- Settings are available for automated system and manual operation - We provide different customized services for the workload and environment.