Aircraft depainting and repainting

-

01

01

Paint removal

-

Chemical

A chemical mixture of hydrogen peroxide and other ingredients is sprayed onto the aircraft surface using a spray machine.

-

Physical

Sanding :Grind and peel off the paint (0.6mm) using a sandpaper grinder rotating at 12,000 revolutions per minute

Blasting : Removal of paint by spraying fine plastic or metal particles onto the painted surface at high speed.

-

Chemical

-

02

02

Aircraft washing/surface treatment

Wash with solvent at room temperature / Dry for 1 hour

Oxide film formed with Aerodyne solution -

03

03

Paint 1 (primer)

A process to protect the aluminum on the aircraft surface and increase the adhesion of the paint

-

04

04

Painting 2 (top coating)

Forms static electricity and attaches paint by attraction

-

05

05

Marking

To prevent contamination, the entire aircraft is covered with vinyl and then letters and logos are marked

-

06

06

Return to service

Refers to the state in which the aircraft can operate after painting work has been completed

Problems with removing old paint

When removing paint with the conventional method, it causes a large amount of secondary pollutants and is dangerous to workers because the paint remover is toxic.

View existing paint removal work video [EBS Clip Bank] Fighter maintenance window - Paint removal workVictex depainting technology

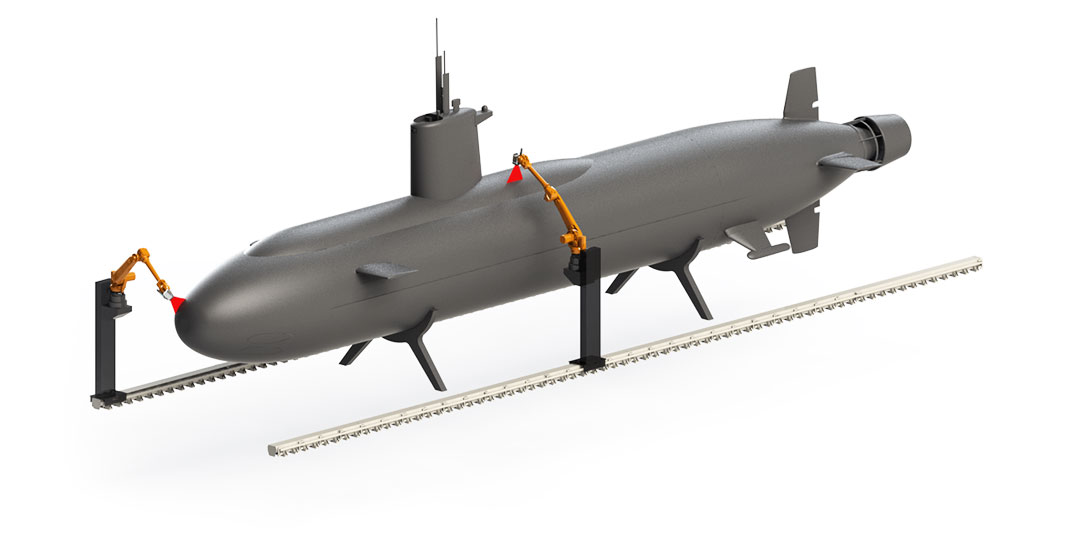

Victex Co., Ltd. Introduced a new method for paint removal → Provides a safe working environment for paint removal workers with laser and does not generate secondary pollutants

In 2016, the company developed a depainting automation equipment that removes paint using a laser and delivered it to the Air Force.